Series Brief

GMD series diamonds are high quality metal bond grinding abrasives. It is produced with high purity raw material, advanced equipment, self developed synthetic technology and advanced sorting process.

Nine grades can meet the requirements of high sharpness electroplated products and high toughness bronze products, they are widely used in processing glass, ceramics, carbide, magnetic materials, etc.

Remark: Based on different raw materials and production processes, CRC, CRJ, GMDP diamond wheel grits are available to meet different needs.

Grades Desription

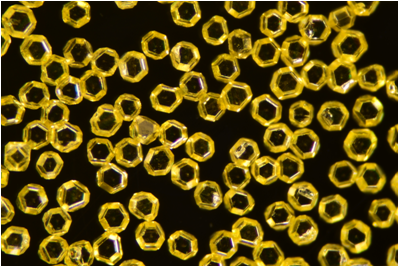

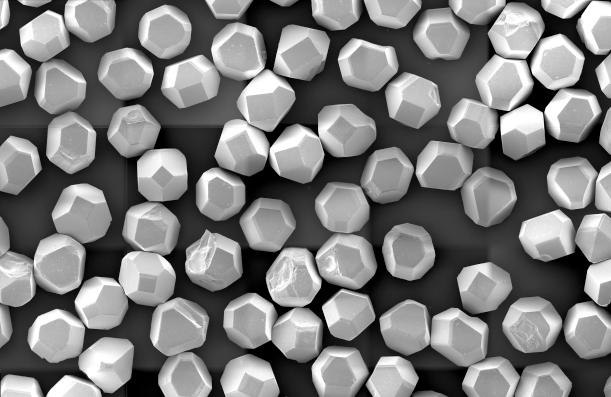

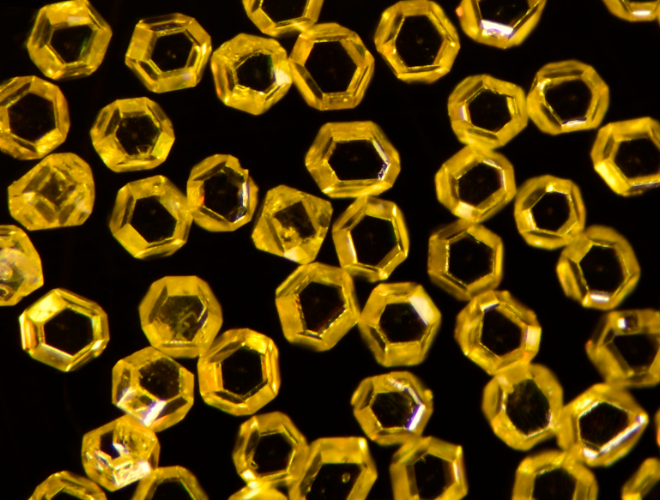

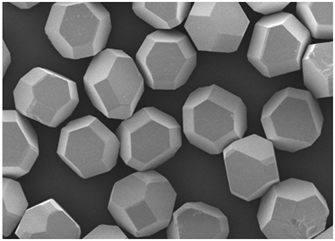

GMD650 is a polyhedron diamond with regular hexahedron and octahedron crystal shape. High transparency, low impurity, high toughness and thermal stability. It is suitable for environment where the impact load is large and the product is required to maintain a good shape.

GMD210 consists of a multi angled crystal with good sharpness, relatively low impact toughness, a lot of sharp edges. Its fragility is the best in the GMD series. It is suitable for the lower load grinding and large area contact processing applications.

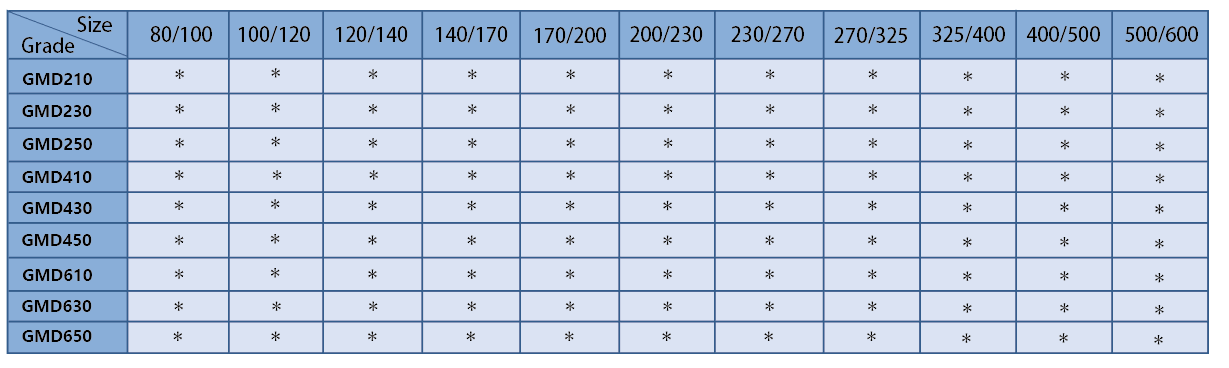

Available sizes is from 80/100 to 500/600, it can also be tailor-made for customers to meet their individual needs.

Available grade & size ( * available )

Remark: Special size range could be customer-oriented.

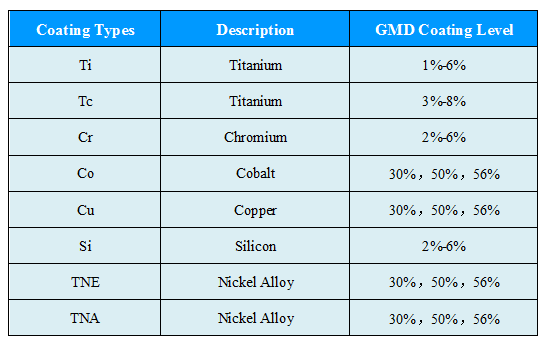

Coating Brief

Coating generally improves the wettability of the diamond, making the retention between the diamond and the bonding agent stronger. At the same time, the coating can also protect the diamond from the corrosion of materials such as metal powder in the formulation, thereby prolong the life of the tool.

The coating and coating level is as follows:

Note: The coating and coating level can be customized according to customers' requirement.

Application Recommend

Diamond wheel grits are widely used in the glass, ceramics, carbide, gem, mold manufacturing industry, etc .

u Machine tools, mold manufacturing industry

Ultra-thin grinding wheel for precision cutting and grooving, metal cutting wheel, electroplating grinding wheel.

u Glass, ceramics, refractory industry

High-precision ultra-thin cutting wheel, edging wheel for optical glass, metal bond core bit.

u Automotive, refrigeration, bearing industry

Dressing roller, precision electroplating grinding wheel, special grinding wheel for compressor parts, electroplating grinding disc , cutting blade for automobile brake pad, grinding wheel for automobile glass.

u Carbide, non-ferrous metal industry

Electroplating grinding wheel, electroplating shaped grinding wheel, metal bond parallel grinding wheel, metal bond centerless grinding wheel.

u Magnetic material

High-precision ultra-thin cutting wheel, metal bond grinding wheel.

u Gem Industry

Electroplated grinding wheel, metal bond grinding wheel.

For example,

- Application

- Construction

- Oil & Gas

- Glass

- Mine & Geology

- Ceramic

- Machinery

- Gem

- Other

- Service

- Sample Application

- Online Message