Series Brief

The hardness of cubic boron nitride CBN is second only to diamond, its thermal stability is better than diamond, it is not easy to react with ferrous metals during processing. Therefore, it is widely used in the cutting of various tool steels, alloy steels and cast irons.

Cubic boron nitride is formed by converting hexagonal boron nitride by a press under high temperature and high pressure.

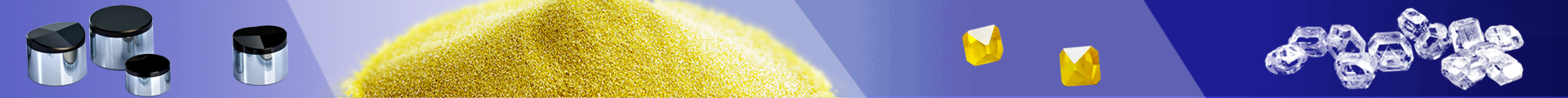

CR GEMS' cubic boron nitride is divided into GBN-A ,GBN-B ,GBN-Z,GBN-T.

It is suitable for various bonds such as resin, metal, electroplating, ceramics, etc. It can improve tools' life span in the industry of machining, reduce replacement times, increase the productivity of equipment. Its excellent sharp performance greatly reduces the power consumption of the equipment. The processing cycle thus greatly reduces the cost. Good thermal conductivity effectively prevents burns on the surface of the workpiece, which improves the surface quality and machining accuracy of the work piece.

GBN series products can be coated with different materials on the surface according to different bond and application conditions. The coating can effectively improve the retention between bond and GBN, enhance the thermal conductivity, and make GBN tools more excellent performance.

Application Recommend

u Machine tools, Mould manufacturing Industry

CNC grinding machine with CBN grinding wheel, conventional CBN grinding wheel, CBN high precision ultra-thin cutting wheel

u Automotive, refrigeration, bearing industry

Ceramic bond CBN grinding wheel for groove grinding, CBN grinding wheel for camshaft grinding, CBN grinding wheel for crankshaft grinding, CBN grinding wheel for compressor parts processing, vitrified wheel for internal circle grinding.

For example,