Series Brief

CR GEMS has specialized production facilities, modern technical center and advanced inspection equipments, strictly control the indexes of products to produce high quality micro diamond powder of GMP series.

This series diamonds are mainly used in cutting, grinding and polishing of apphires, optical glass, metal and composite materials. It can also be used in the manufacture of PDC.

Quality Control -[RESIPC]

Raw material Environment Surface cleaning

Internal impurity Particle size distribution Crystal shape

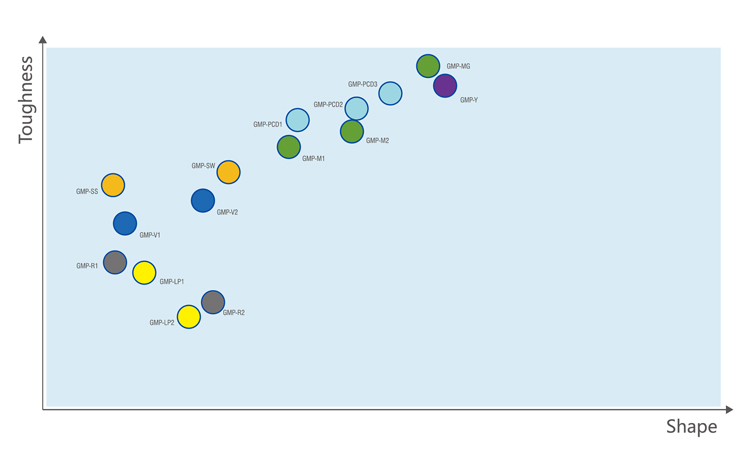

Remark: Based on different raw materials and production processes, GMP1/2/3 and CRW micro diamond powder are available to meet different needs.

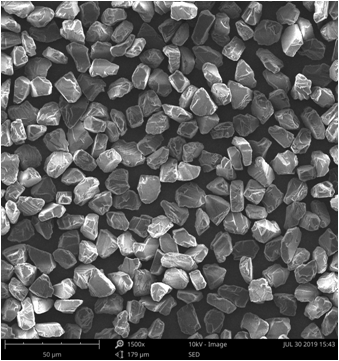

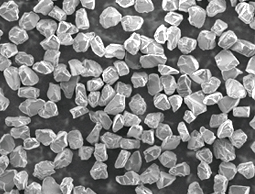

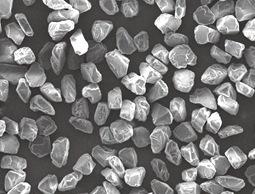

GMP-S Series for Slicing

Monocrystalline micro diamond powder, 3-D block shape, sharp cutting edges, uniform shape and narrow particle size distribution.

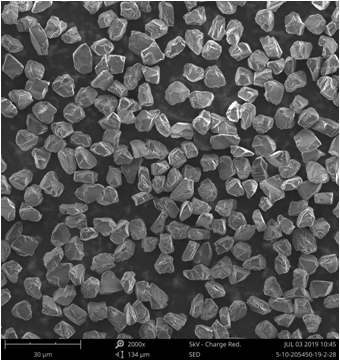

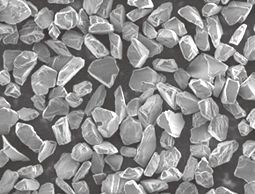

GMP-M Series for Metal Bond Tools

Monocrystalline micro diamond powder, 3-D blocky particle shape, high purity, good mechanical strength, strong impact resistance when grinding. High purity can avoid expansion in the crystal during sintering, improve the mechanical strength of diamond particles, and extend the tool's life span.

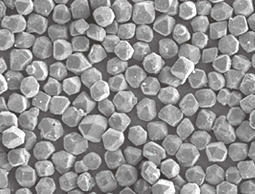

GMP-MG Grown Micro Diamond Powder

Grown micro diamond powder, with very complete shape, high strength, good thermal impact resistance, high surface cleanness, relatively concentrated particle size distribution.

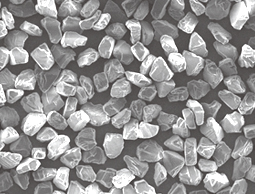

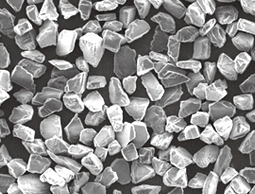

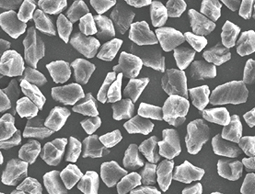

GMP-R Series for Resin Bond Tools

Irregular fragile shape, sharp cutting edges, easy to break down during grinding, high grinding efficiency. Clean surface enables good retention between resin and diamond, extend tool's life span.

GMP-V Series for Vitrified Bond Tools

Monocrystalline micro diamond powder with good self-sharpening, easy to break away from the particle, good wettablility with vitrified bond.

GMP-LP Series for Lapping & Polishing

GMP-LP1:Monocrystalline micro diamond powder, high purity, isomorphic particle shape, narrow particle size distribution.

GMP-LP2:Polycrystalline micro diamond powder ,multi micro cutting edges, good shape consistency, superior friability, relatively narrow particle size distribution.

GMP-PCD Series for PCD

3-D blocky particle shape and high surface cleanness. In the process of sintering, the surface ion control can highly enhance the retention and its high purity can reduce the damages which caused by impurities as well. Good shape uniformity and high mechanical strength of crystals can dramatically improve the quality of PCD.

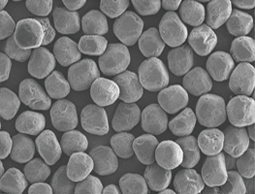

GMP-Y Round Diamond

Rough surface, spherical shape, relatively high purity. The spherical shape can improve the precision during the grinding, while the numerous free cutting edges on the surface help to improve grinding accuracy.

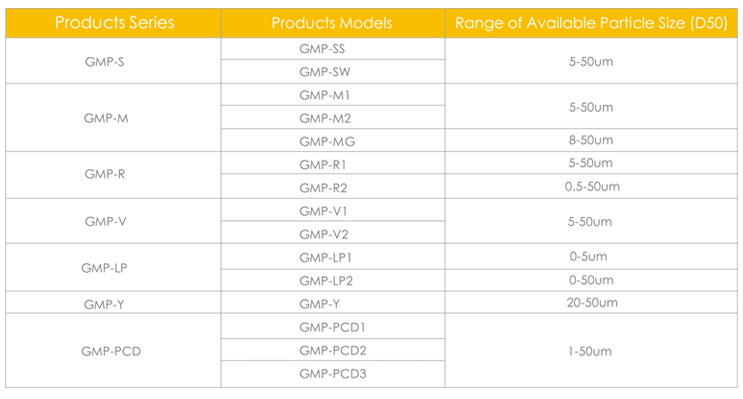

Available Size of GMP

Coating Brief

The coating layer of micro diamond powder could increase the diamond's toughness, the retention between the diamond and bond, as well as to prevent the diamond from being oxidized and graphitized. Especially for resin bond tools, the coating could effectively relieve the damage to the bond, therefore prolong the tool's life.

GMP -Ti Feature:

Tight coating, without aggregation, can protect diamond from corrosion by carbon fusion

bond during sintering, and improve the retention between diamond and bond.

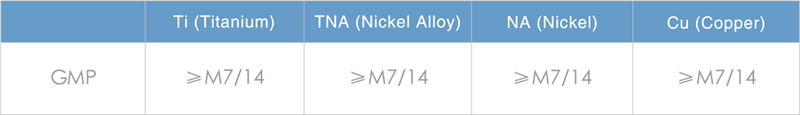

Available coating:

Remark: The coating and coating level can be customized according to customers' requirement.

Application Recommend

u It is suitable for diamond dicing blade. The blade made by this diamond is sharp and could minimize the chips when cutting glass. The retention between diamond and bond is increased to improve tools' life span whether by sintering or electroplating.

u It is used to produce polishing paste and polishing suspension. Due to its excellent sharpness, there is no scratch during polishing, and thus the machining accuracy can be improved. It is widely used in the processing of ceramics, wire drawing dies, PCD, optical glass, etc.

u It is applicable to the production of polycrystalline diamond, Polycrystalline drawing dies, PCD, etc.

- Application

- Construction

- Oil & Gas

- Glass

- Mine & Geology

- Ceramic

- Machinery

- Gem

- Other

- Service

- Sample Application

- Online Message