Series Brief

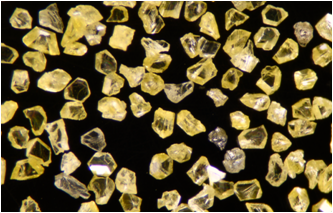

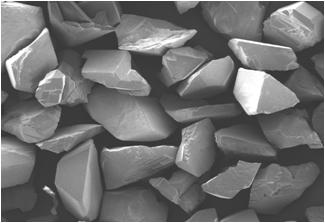

GRD series diamond consists of single crystal diamond and polycrystalline diamond. GRD10 and GRD20 are single crystals with polygonal shapes, blocks and flakes. They have good sharpness. They are suitable for bonds such as resin and ceramics.

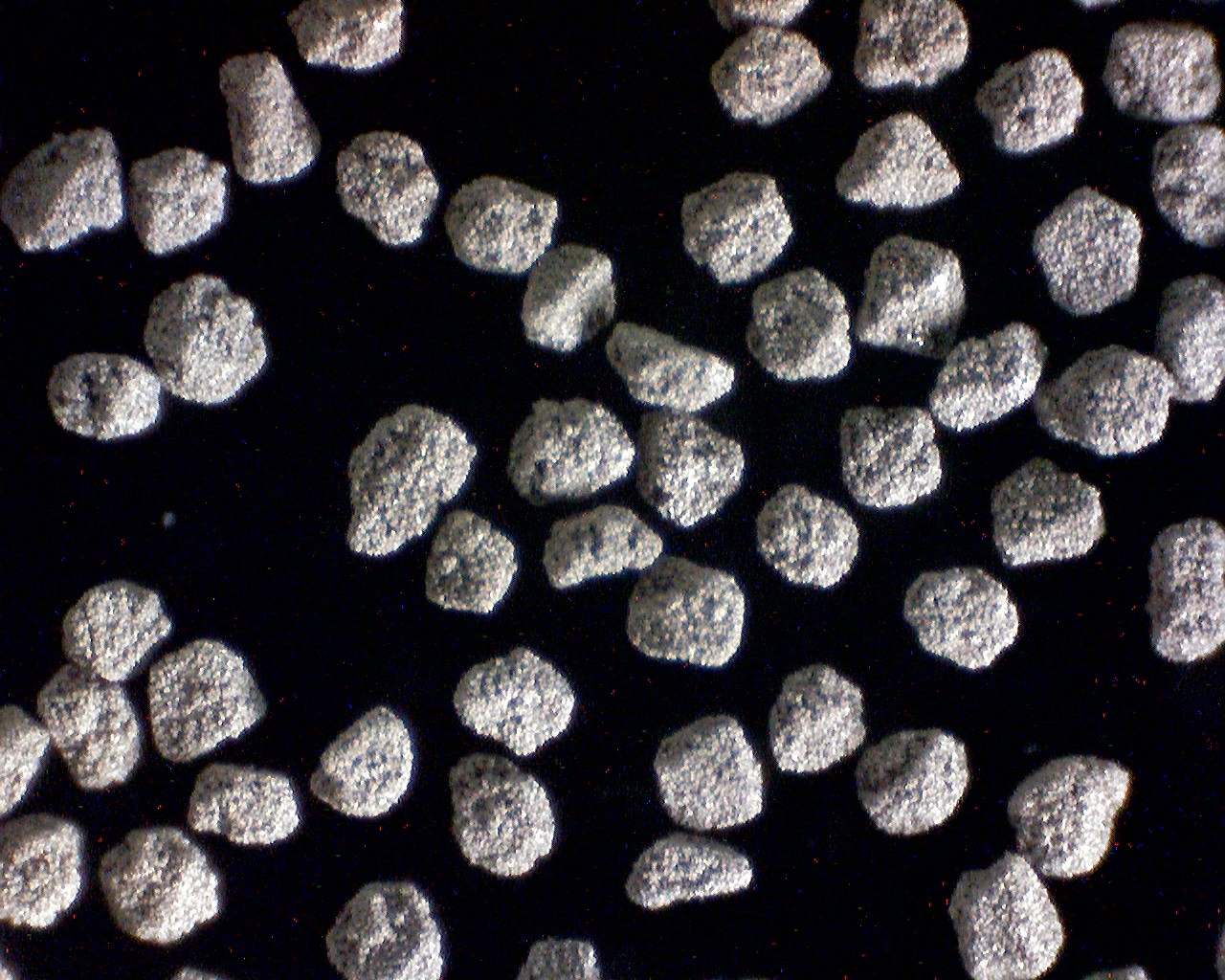

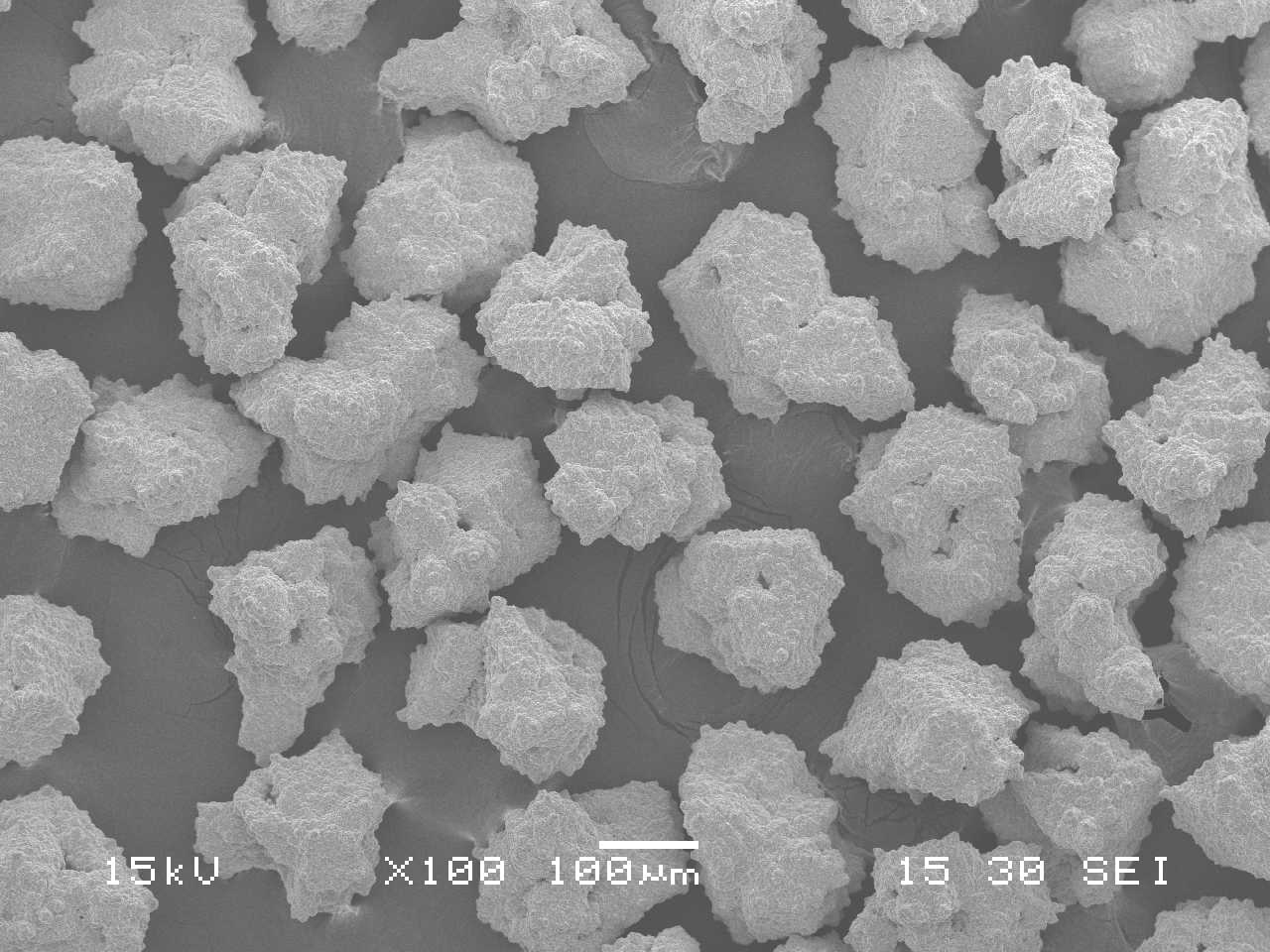

GRD40 and GRD60 are polycrystalline diamonds, which are irregular shape and composed of many fine grains. Due to their unique shape and micro crushing properties, GRD polycrystalline abrasives have very good self-sharpness and can greatly improve grinding efficiency, thereby reduce energy consumption and save the cost.

Available grade & size ( * available )  Note: Special size range could be customer-oriented.

Note: Special size range could be customer-oriented.

Grades Desription

GRD10 series is composed of irregular needle-shaped and angular crystals, with great sharpness. They are recommended to grind materials that demand large removal rate and less grinding impact, like tungsten carbide, functional ceramics, etc.

GRD20 series diamonds consists of angular crystal, its impact resistance is much limited, it is applicable for low impact and large removal rate. It could be applied in electroplated and vitrified bond tools.

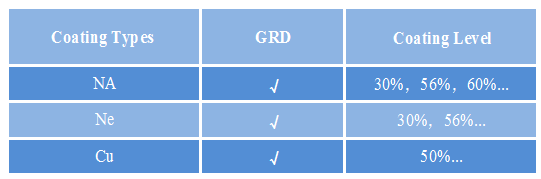

Coating Brief

GRD abrasives exhibit better performance in different binders after different coatings.

Generally, the wettability of the diamond can be improved, the holding force between the diamond and the binder is stronger.At the same time, it can greatly improve the heat dissipation performance of the tool and reduce the surface burn for the workpiece.

Available coating and coating level

Remark : NA/Ne-nickel, Cu-copper, the coating and coating level can be customized according to customers' requirement.

Recommend Application

u Machine tool, mold manufacturing industry -resin integral cutting wheel, resin grinding wheel for CNC grinding machine.

u Glass, ceramics, refractory industry - resin bond grinding wheel.

u Automotive, refrigeration, bearing industry - resin bond grinding disc.

u Carbide, non-ferrous metal industry - resin bond grinding wheel, ceramic bond grinding wheel.

u Magnetic material - magnetic material cup-shaped surface grinding wheel.

u Gems industry - resin bond grinding wheel.

For example,

- Application

- Construction

- Oil & Gas

- Glass

- Mine & Geology

- Ceramic

- Machinery

- Gem

- Other

- Service

- Sample Application

- Online Message